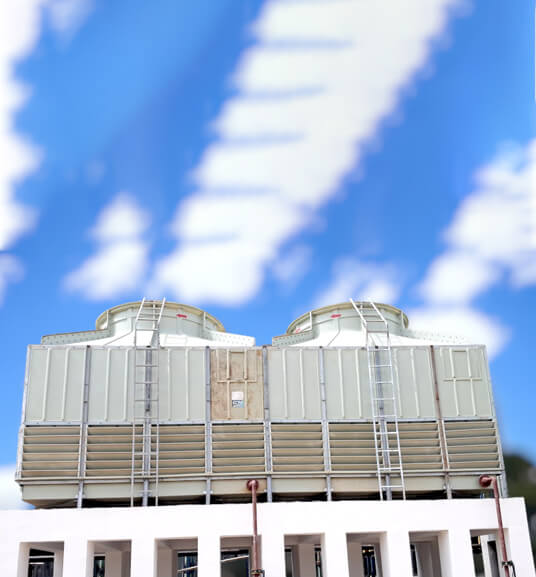

KR SERIES COOLING TOWERS

Counterflow cooling towers play a crucial role in cooling water for industrial and HVAC applications by utilizing a countercurrent flow principle. In a counterflow tower air travels in the opposite direction (counter) to the direction of the falling water. Hot water enters the tower and spreads over fill media, which provides a large surface area for efficient heat exchange with the upward-moving air drawn in by fans or natural draft. This process, known as evaporative cooling, facilitates the transfer of heat from the water to the air. Cooled water is collected at the tower’s bottom and circulated back for reuse, while hot, moisture-laden air exits from the top. The countercurrent flow enhances heat exchange efficiency, allowing for a greater temperature difference between the water and air. Recognized for their efficiency, compact design, and versatility in handling diverse heat loads, counterflow cooling towers are extensively employed across industries to dissipate heat from various processes and maintain optimal operating temperatures.

KEY FEATURES

CTI certified

Our cooling tower is CTI certified, with components complying to CTI STD.

MOC

MOC: MSHDG / PULTRUDED FRP

Fan Motor

Branded Electric Motor with Standard IE2 Motor with option of IE3 / IE4/ FLP / VFD*

Driven System

Gear less direct drive.Ladder Platform

Ladder, platform and safety railing facilitate ease of maintenance.

Axial Fan

Axial Fans with aerodynamic design blade profile, with dynamic balancing standard G6.3 balanced fans

FRP Louver

Water and sight tight design that minimizes splash out and the potential for algae formation inside the tower.

Single Cell

Single Cell Capacity 15-482 CMH - Multi cell option available.

Smooth Finish

Aesthetic smooth finish on both sides of FRP panel and water basin.Ladder Platform

Ladder, platform and safety railing facilitate ease of maintenance.HIGHLIGHTS

ASSEMBLY AND AVAILABILITY

FILLS

THERMAL CAPACITY

Multi Cell: 80TR to 3000TR

MATERIAL OF CONSTRUCTION

DETAILS

The “KR Series,” is a line of cooling towers meticulously crafted for various industrial sectors, with a particular focus on Chemical, Pharma, Food Processing, and Data Centers. These towers are meticulously engineered to optimize energy efficiency, addressing specific on-site needs and minimizing energy losses in components such as motors, fans, and transmission drives. The design enhancements contribute to an overall improvement in the cooling towers’ performance, while also facilitating easier maintenance of the entire unit.