Adani Mundra Case Study

Cooling Tower Solution

SEA WATER APPLICATION

MSTPL is a solar PV manufacturer having 4 GW cells & modules and 2 GW of ingots & wafers manufacturing capacity. Company claimed to achieve 100% reuse of sewage treatment plant (STP) treated water and 50% reuse of effluent treatment plant (ETP) treated water, minimizing freshwater withdrawal so for such an application a cooling tower with high resistance against corrosion plays an important role in achieving the milestones. SS 316 material with additional molybdenum makes it one of most corrosion resistant material available to use in CT application.

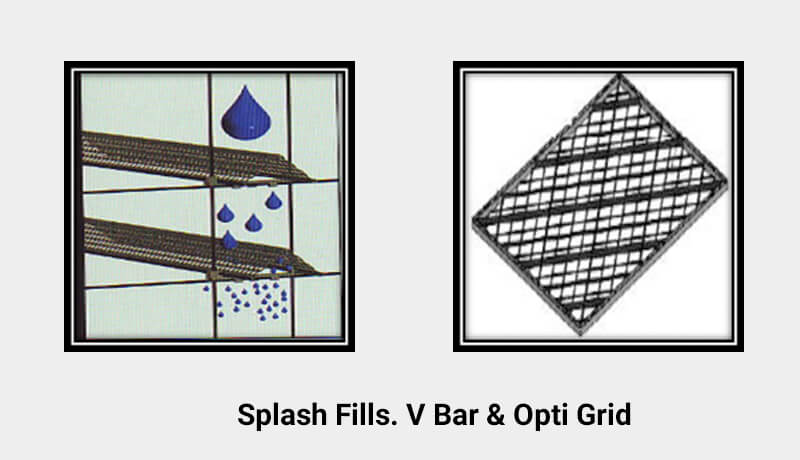

Fill Selection

OPTIMUM PERFORMANCE

Fill selection plays a very crucial role in cooling tower performance as it is responsible for the heat transfer process. Based on the water application fills should be selected which results in longer operation with lesser maintenance cost and ultimately provides saving in cost of operation.

In 2024, ACTPL Successfully commissioned Cooling tower with full Stainless steel [Grade 316] Structures and Modular splash fills in “Mundra solar technologies PV ltd.” owned by ADANI group. The overall cooling capacity of the project was around 21,164 TR with Single CT capacity of 1600 CMH [2645 TR].