Know About Cooling Tower Fills – The Heart of CT

How cooling is achieved in CT?

Wet type Cooling towers are devices that use water evaporation to cool down water. They are widely used in industrial processes, power plants, and air conditioning systems. Cooling towers are designed to maximize the heat transfer between the water and the air, and one of the key components that affect this process is the cooling tower fill as the heat transfer takes place at fills.

The cooling in these cooling towers is achieved in two ways Droplet cooling or Film cooling.

What is Cooling Tower Fill?

Cooling tower fill is a medium that is placed inside the tower to increase the surface area for the water-air contact. The more surface area, the more heat transfer and evaporation can occur, and the lower the water temperature will be. Cooling tower fill can be made of different materials, such as PVC, polypropylene, wood, or metal, depending on the application and the water quality.

The fills are categorized as Film fills (produces film for cooling effect) and Splash fills (produces droplets for cooling effect). Each type has its own advantages and disadvantages, depending on the cooling tower design, operation, and maintenance.

Splash Fill

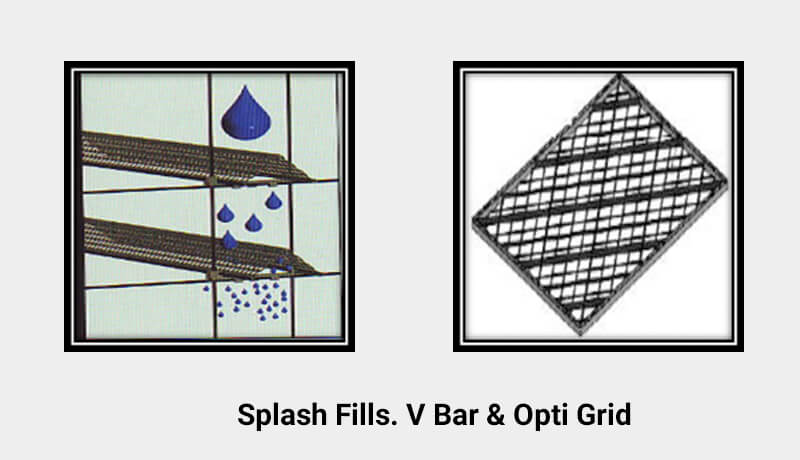

Splash fill consists of layers of bars, slats, grids, or blocks that break the water into small droplets as it falls through the fill. The droplets create a large surface area for the air to contact and cool the water. Splash fill is suitable for cooling towers that handle water with high levels of solids, debris, or biological contaminants, as it is less prone to clogging and fouling. However, splash fill is less efficient than film fill, as it requires more air flow and fan power to achieve the same cooling effect.

Figure: Splash Fills. V Bar & Opti Grid

Film Fills

Film fill consists of thin sheets of corrugated or textured material that form channels or flutes for the water to flow through. The water forms a thin film on the surface of the fill, which increases the heat transfer and evaporation rate. Film fill is more efficient than splash fill, as it requires less air flow and fan power to achieve the same cooling effect. However, film fill is more susceptible to clogging and fouling, especially if the water contains high levels of solids, debris, or biological contaminants.

Figure: Film Fills

The way these flutes are arranged further classify and change their behaviour against the quality of water.

It is depicted in following figure:

Figure: Film Fills classification based on the flute design.

The standard available fills are having 12 / 19 / 21 mm of pitch. However, industry the Flute misnomer is used for the pitch of the fills.

One often hears that the efficient fills are 12 mm fluted, what he / she is referring here is that the pitch size is of 12 mm and not flute size.

MODULAR SPLASH FILLS

Film fills are more efficient ones but cannot tolerate poor water quality, Splash fills are less efficient but can tolerate poor quality water. To overcome the issues of both and to gain the advantage of both the fills, the new type of fills (Based on Droplet formation principle) is introduced i.e. Modularity of film fills and principle of Splash fills. These are called as Modular Splash fills.

Figure: Modular Splash Fills.

Problems with Selection of Wrong Fill

The selection of the right fill for a cooling tower is crucial for its performance, reliability, and longevity. Choosing the wrong fill can lead to several problems, such as:

Therefore, it is important to consider the following factors when selecting the fill for a cooling tower:

Some discussion on Fills selection or for Retrofit.

This scenario assumes the water quality available is poor.

If the user selects film fills shown as red line, then as water quality is not good, the fills starts to get fouled and their performance deteriorates continuously until it is significantly low. At this point a general approach is to either clean the fills or replace them. However in both the cases the deterioration continues.

In other way, if modular splash fills are used here, as their tolerance limits for the poor quality water is high, they don’t get affected the water and performs at nearly steady levels. Even though, their operating performance line is below – if compared to new film fills- over the time period they outperform the film fills and do not require any cleaning and / or replacement often.

To be able to select the correct fills, following table makes it easier for the user. If you follow following table guidelines, you will be better off with your selection as far as fills are concerned. However, there are other parameters also need to be considered, like space available for the cooling tower etc.

Figure: A ready reckoner for the selection of fill type based on water quality available at site.

To Summarize, Cooling tower fill is a vital component of cooling towers that affects their cooling capacity, energy consumption, and maintenance costs. Therefore, it is essential to select the right fill for a cooling tower, considering the water quality, the cooling tower design, and the cooling tower operation. By doing so, you can ensure the optimal performance, reliability, and longevity of your cooling tower.

For any of the queries and to know more about Cooling Towers in general or Fills in particular, please contact your nearest ACTPL representative, else simply mail us at: sales@advance2020.com